Composition of joint:

The national patented product "WL double screw sleeve reinforcement joint" independently developed by Beijing Wulongxing Technology Development Co., Ltd. is mainly characterized by "reinforcement non rotation" connection. It has the characteristics of fast connection speed, convenient construction, reliable quality, low cost and all-weather construction

Composition and characteristics of WL double screw sleeve new reinforcement joint

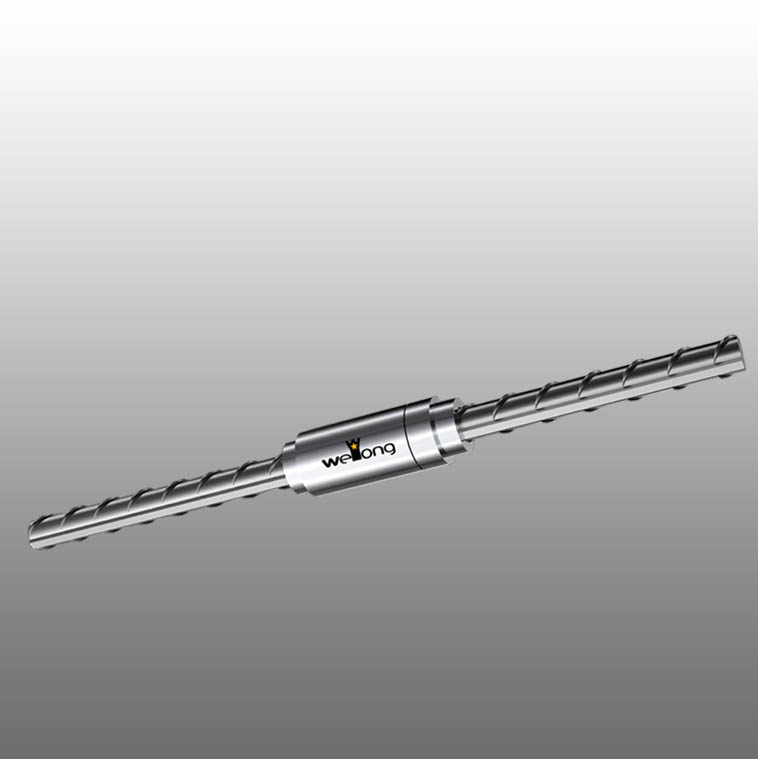

Composition: the connector is composed of inner screw sleeve 1, inner screw sleeve 2, outer screw sleeve and lock nut.

Features: the connection operation can be completed without rotating the reinforcement. It is especially suitable for the overall connection of bundled reinforcement with large positional error in building parts and reinforcement parts. The construction is convenient, reliable and low cost.

Connection principle of "double screw socket joint" and position requirements of reinforcement to be connected:

Comparison before and after connection correction

- No matter the connection of single or bundle reinforcement, the "non plug-in" connection of reinforcement can greatly reduce the centering requirements of reinforcement. Even if the radial deviation of connecting reinforcement is large, tools can be used to facilitate the connection after correction;

- "Double screw socket joint" solves the connection problem when the thread trace lines of two rebar thread heads do not coincide in the connection of straight thread reinforcement;

- The axial clearance of connecting reinforcement is 0-20mm, which can meet the requirements of joint deformation performance when the middle is not top.

Connection characteristics of reinforcement construction

- There is no wet operation at the connection joint, and it is fully mechanically connected;

- The connection is fast and takes only 20 seconds. After the connection is completed, it can bear the force;

- Whether the reinforcement connection quality is qualified or not can be visually inspected, which is simple and clear;

- The field joint quality inspection is simple and fast, which is consistent with the ordinary straight thread joint;

- There is no need for other machines and tools and equipment on the reinforcement connection working surface, but only the connection wrench.

Construction method of integral butt joint of "WL double screw sleeve reinforcement joint" in reinforcement cage

After steel bar threading, mold tooling or steel bar cage forming machine cage shall be adopted.

1. Connect the inner screw sleeve 1 to the lower reinforcement cage. 2. Connect the inner screw sleeve 2, outer screw sleeve and lock nut to the upper reinforcement cage.

3. Place the lower reinforcement cage into the hole pile. 4. Lifting and docking of upper reinforcement cage.

5. Align the upper and lower reinforcement cages 6. Connect WL double screw socket joints one by one and tighten them

Complete the overall butt joint of reinforcement cage

五隆興科技發(fā)展有限公司

五隆興科技發(fā)展有限公司