As the skeleton supporting each high-rise building

Reinforcement is an indispensable element in the construction site

Lifting site operation

Many people may think of construction workers

The sun or the cold wind overhead

Steel bars are machined into different shapes by machine or hand

(the picture comes from the Internet and is infringed and deleted)

At the traditional processing site

Temporary reinforcement processing shed needs to be built

Occupation of construction land

(the picture comes from the Internet and is infringed and deleted)

The scientific processing and production management of reinforcement cannot be realized on the construction site

The utilization of saturated capacity of reinforcement equipment cannot be guaranteed

It leads to large loss of reinforcement and low processing efficiency

in addition

In traditional mode

The reinforcement construction of cast-in-situ system needs to be bound on the site floor

It takes a lot of manpower to bind the reinforcement

The efficiency of reinforcement installation and construction is low

There are many potential safety problems when a large number of personnel work in the working face

But…

All these difficulties have been solved now!!

In order to accelerate the transformation and upgrading of the construction industry

Bozhilin planned and designed

New intelligent integrated processing and distribution center for formed reinforcement

Promote the implementation of “reinforcement industrialization and integration”

New intelligent centralized processing and distribution center for formed reinforcement

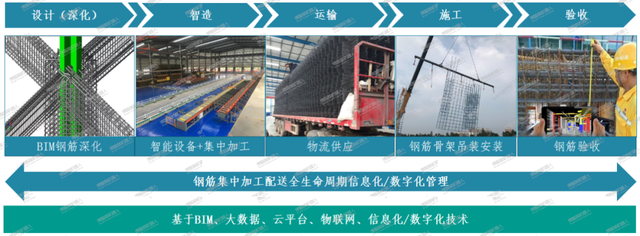

Apply the full life cycle management mode integrating design (deepening) → intelligent manufacturing → logistics supply → construction → acceptance to reinforcement engineering, promote the collaborative work of all links and participants of reinforcement professional subcontracting, and promote the implementation of “reinforcement industrialization and integration”.

Whole process of centralized processing and distribution of reinforcement

Let’s give you a detailed introduction

Operation mode of new intelligent centralized processing and distribution center for formed reinforcement

GO !

01 Reinforcement deepening design

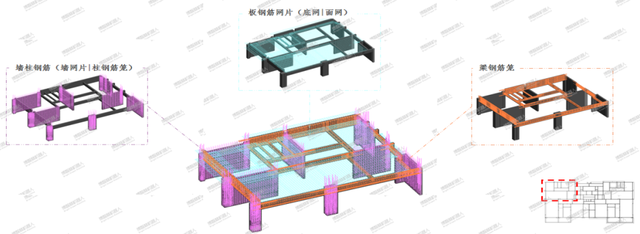

The components of the current standard floor are divided into shear wall mesh, slab bottom mesh, slab surface mesh, beam reinforcement cage and column reinforcement cage.

Standard layer component splitting

02 Intelligent equipment + centralized processing

Through the use of intelligent processing equipment such as mesh, bar, stirrup, beam and column reinforcement cage and curved mesh stacking, the formed stirrup, beam and column reinforcement cage skeleton and welded mesh are produced to maximize the use of factory reinforcement raw materials. Based on the cutting strategy of fixed-scale bar and mesh scheduling, the utilization of reinforcement raw materials in the factory is optimized and the waste ratio of raw materials is reduced, The processing platform is uniformly scheduled through the information system.

03 Logistics transportation and reinforcement construction

Establish a third-party transportation system to transport the intensively processed formed reinforcement to the construction site for direct installation, which is quite different from the reinforcement binding of the traditional cast-in-situ system. The reinforcement construction efficiency is high, the main construction cycle is short, and the economic benefit is greatly improved compared with the traditional construction mode.

Transportation and construction of formed reinforcement

Centralized processing and distribution of new intelligent formed reinforcement

Digital design, intelligent production and intelligent construction are realized

It has great advantages for project implementation

(1) Material saving advantage

Using the processing and distribution method of formed reinforcement, the processing factory promises the yield to customers. It can comprehensively cut the material size of the whole project or multiple projects, and use the abundant site of the factory to classify and store the surplus materials by size, and then use them later, so as to reduce the generation of surplus materials and waste materials.

(2) Quality management advantages

The formed steel bar processing plant has accurate blanking size and high precision of processed products, and can provide high-precision processing components. Raw materials, semi-finished products, finished products and surplus materials are stored indoors, which will not produce reinforcement corrosion and effectively ensure the quality of reinforced concrete components.

(3) Schedule management advantages

The large-scale industrial production mode is adopted for reinforcement processing and forming in the formed reinforcement processing plant, with high output per unit time, which can meet the short-term mass production demand for reinforcement processing due to the tight construction period on the construction site. At the same time, the forming reinforcement processing plant is not affected by natural conditions such as time, rainy season and temperature, and can produce 24 hours a day, greatly shortening the construction period of the construction site.

(4) Safety management advantages

The formed steel bar processing plant is built in strict accordance with the production-oriented processing enterprise, and has strict requirements in terms of lifting, hoisting, power consumption and mechanical protection in safety management, which greatly reduces the probability of safety accidents.

(5) Technical advantages

The processing and distribution of formed reinforcement are integrated. The technology adopts the team cooperation mode, and the software is used for proofing, which can realize information sharing. The proofing personnel are multiple collaborative cooperation, and there will be no phenomena such as missing the drawings. Moreover, the proofing is standardized, the material list is concise and clear, the materials can be technically optimized, and the layout drawing and material plate can be issued according to the on-site construction flow section.

(6) Material control advantages

The processing of formed reinforcement shall be strictly managed and controlled in terms of raw materials and waste materials, so as to realize the dynamic management and information sharing of raw materials, finished products, surplus materials and waste materials every day. It shall be managed in strict accordance with the daily management process of raw materials, finished products, surplus materials and waste materials, and there will be no disadvantages in the traditional mode.

The new intelligent integrated processing and distribution platform for shaped reinforcement integrates industrial technologies such as deepening design, sample turning, production scheduling and control, logistics transportation, hoisting and installation, and realizes digital design, intelligent production and intelligent construction. More accurate control is realized from the whole process of planned procurement, raw material management, blanking optimization, processing process monitoring, processing finished product management and reinforcement finished product hoisting construction management, so as to effectively solve the problems of large labor input, low efficiency, high loss, non-standard quality, high capital cost and large area of operation site.

So it seems

Bozhilin’s new intelligent forming reinforcement centralized processing and distribution platform

You can make your debut in position C~

五隆興科技發(fā)展有限公司

五隆興科技發(fā)展有限公司