Principle of reinforcement radial extrusion connection

The axial extrusion connection of reinforcement is to squeeze the steel sleeve and insert two butt reinforcement towards its axis by using extruder and pressing film, so as to make the sleeve bite into the ribs of ribbed reinforcement and combine them into one, as shown in the figure.

Radial extrusion connection of reinforcement

(1) In order to accurately judge the length of the reinforcement extending into the steel sleeve, first draw the paint mark line with a ruler at both ends of the reinforcement.

(2) Select and match the sleeve with the die.

(3) Connect the power supply of the pump station and the ultra-high pressure oil pipe with the semi extruder (or extruder).

(4) Start the pump station, press the “up” and “down” buttons of the manual switch, reciprocating the oil cylinder several times, and check whether the pump station and the semi extruder (or extruder) are normal.

(5) Generally, half of the reinforcement joints are crimped in advance, and then transported to the operation site for the whole crimping connection of the other half of the reinforcement joints.

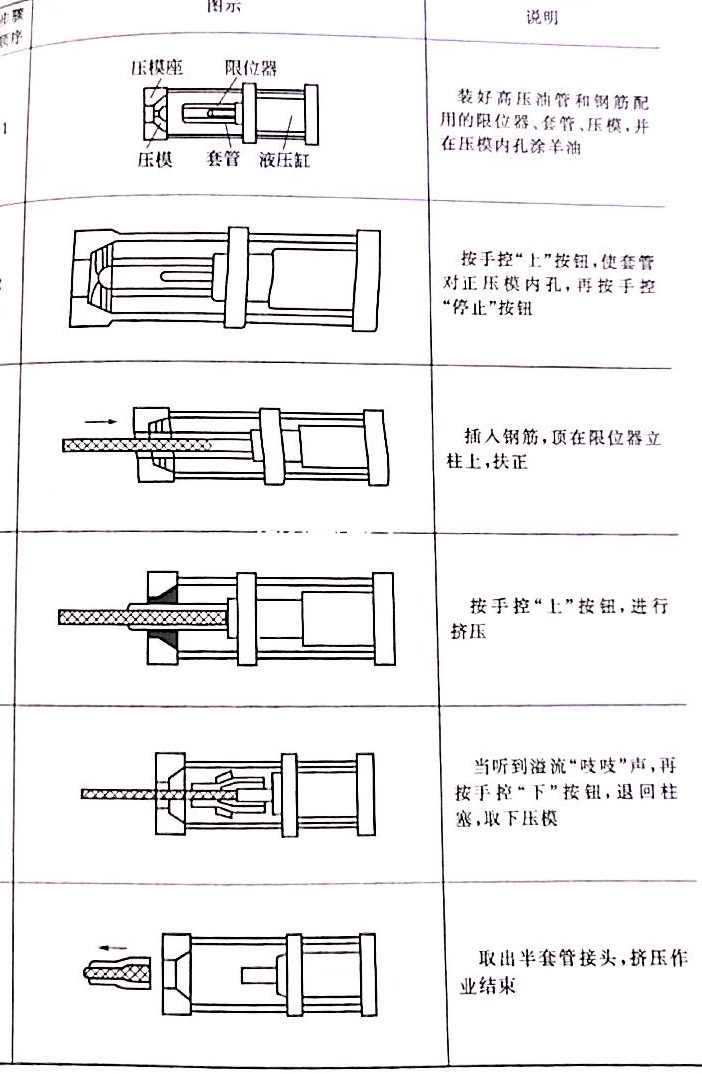

(6) Extrusion operation steps of half reinforcement

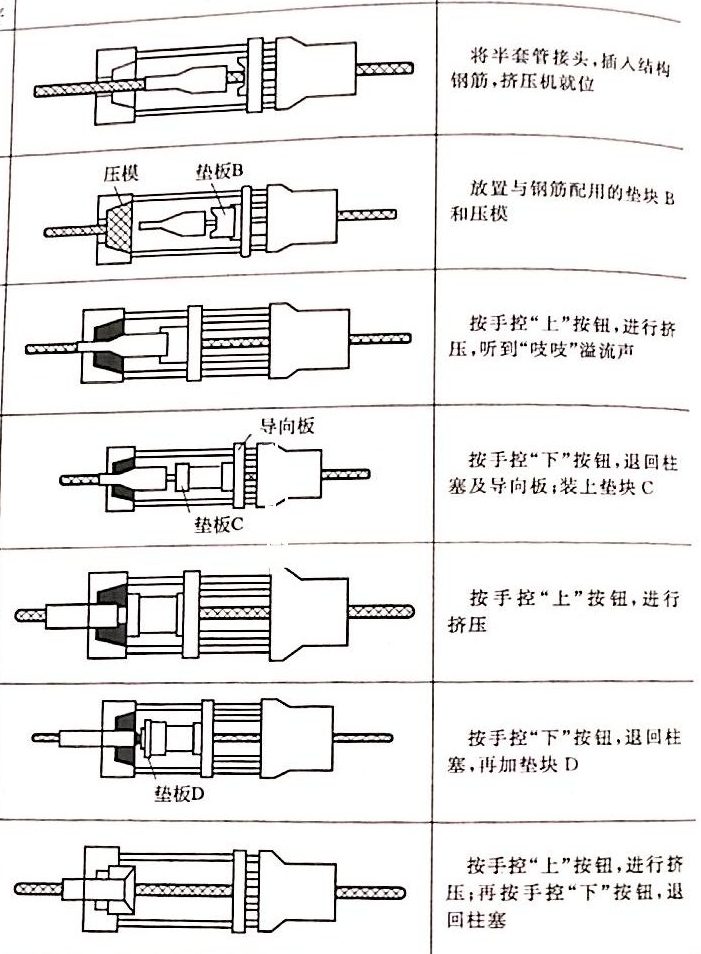

(7) Extrusion operation steps of the whole reinforcement

(8) For the crimped joint, the length of the sleeve wrapped reinforcement shall reach the paint mark line. For the joint that cannot be reached, the measures of binding and reinforcing reinforcement or cutting off and re crimping can be taken.

(9) The compressed joint shall be monitored by gauge, and any sleeve joint that cannot pass through the gauge shall be re pressed once. If it still fails to meet the requirements, it is necessary to change the die for extrusion. After twice extrusion, the sleeve joint still fails to meet the required die and shall not be used again.

五隆興科技發(fā)展有限公司

五隆興科技發(fā)展有限公司